常规以及特种电线电缆定制,国标质量保证,价格合理

电线电缆价格咨询电话:0550-7778262 15385509815

电线电缆价格咨询电话:0550-7778262 15385509815

煤矿用阻燃控制电缆型号及规格参数

[当前栏目:耐候阻燃矿用电缆] [发布日期:2014-08-18]

Fire retardant control cables in mines

产品用途:本产品适用于矿井下交流额定电压为450/750V及以下配电装置中的电器仪表作控制信号保护和测量。

Scope of application:This product is suitable under the mine pit exchanges the rated voltage is 450/750V and in following power distribution equipment electric appliance measuring appliance makes the control Signal protection and survey.

执行标准 Standards implemented : MT818-1999

型号、名称及使用范围 Model descriptions and Use scope

使用特性 Service characteristics

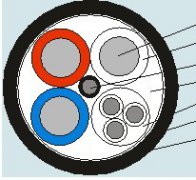

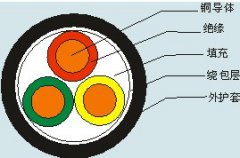

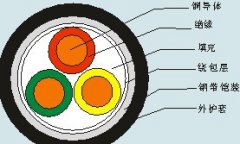

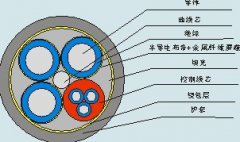

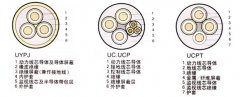

电缆结构示意图

IIIustration of cable structure

型号、名称及使用范围 Model descriptions and Use scope

| 型号Model |

名称 Descriptions |

使用范围 Scope of application |

| MKVV |

煤矿用聚氯乙烯绝缘聚氯乙烯护套控制电缆 PVC insulated PVC sheathed control cables for use in mines |

矿井中一般控制系统中 General control system in mines |

| MKVV22 |

煤矿用聚氯乙烯绝缘钢带铠装聚氯乙烯护套控制电缆 PVC insulated steel tape armored PVC sheathed control cables for use in mines |

矿井中一般控制系统中能承受一定冲击力和压力 General control system cables are under some impact and pressure in the mine |

|

煤矿用聚氯乙烯绝缘细钢丝铠装聚氯乙烯护套控制电缆 PVC insulated fine steel wire armored PVC sheathed control cables for use in mines |

矿井中一般控制系统能承受一定拉力 General control system cables are under some pulling force in the mine |

|

| MKVV42 |

煤矿用聚氯乙烯绝缘粗钢丝铠装聚氯乙烯护套控制电缆 PVC insulated thick steel wire armored PVC sheathed control cables for use in mines |

矿井中一般控制系统能承受较大拉力 General control system cables are under big impact pulling force in the mine |

| MKVVP |

煤矿用聚氯乙烯绝缘铜丝编织屏蔽聚氯乙烯护套控制电缆 PVC insulated copper wire weave shielded PVC sheathed control cables for use in mines |

矿井中强电磁干扰区作一般控制 Strong electromagnetism interference region as general control in mines |

| MKVVP2 |

煤矿用聚氯乙烯绝缘铜带屏蔽聚氯乙烯护套控制电缆 PVC insulated copper tape shielded PVC sheathed control cables for use in mines |

矿井中强电磁干扰区作一般控制 Strong electromagnetism interference region as general control in mines |

| MKVVR |

煤矿用聚氯乙烯绝缘聚氯乙烯护套软控制电缆 PVC insulated PVC sheathed soft control cables for use in mines |

矿井中要求移动场合作一般控制 Request migration situation as general control in mines |

| MKVVRP |

煤矿用聚氯乙烯绝缘铜丝编织屏蔽聚氯乙烯护套软控制电缆 PVC insulated copper wire weave shielded PVC sheathed soft control cables for use in mines |

矿井中要求移动且强电磁干扰区作一般控制 Request migration situation and strong electromagnetism interference region as general control in mines |

使用特性 Service characteristics

|

电缆导体长期允许的工作温度 Long-term service temperature of the cable conductor |

70℃ |

额定电压U0/U Rated voltage U0/U |

450/750V |

电缆敷设温度 Cable laying temperature |

≥0℃ |

| 电缆的最小弯曲半径 Minimun bending radius |

无铠装层的≥电缆外径的6倍,有铠装层或铜带屏蔽的≥电缆外径的12倍, Non armored ≥outer diameter of cable 6 times, armored layer or copper tape shielded≥outer diameter of cable 12times 有屏蔽层的软电缆≥电缆外径的6倍 Shielded layer soft cable ≥ outer diameter of cable 6 times |

||||

电缆结构示意图

IIIustration of cable structure

| 型号 Model |

额定电压 V Rated voltage |

导体标称截面 mm2 Conductor nominal sectional | |||||||

| 0.5 | 0.75 | 1.0 | 1.5 | 2.5 | 4 | 6 | 10 | ||

| 芯数 Core number | |||||||||

| MKVV MKVVP | 450/750 | - | 2-61 | 2-14 | 2-10 | ||||

| MKVVP2 | - | 4-61 | 2-14 | 4-10 | |||||

| MKVV22 | - | 4-61 | 2-14 | 4-10 | |||||

| MKVV32 | - | 7-61 | 4-61 | 2-14 | 4-10 | ||||

| MKVV42 | - | 16-61 | 7-61 | 2-14 | 4-10 | ||||

| MKVVR | 4-61 | - | - | ||||||

| MKVVRP | 4-61 | 4-48 | - | - | |||||

注Note:推荐的芯数系列Recommendation core series:2、3、4、5、7、8、10、12、14、16、19、24、27、30、37、44、48、52、61芯(core)

电缆主要技术性能 Major technical performances

1、 电缆导体直流电阻及绝缘电阻 Cable conductor DC resistance and insulated resistance

2、电缆其它主要技术性能 Other major technical performances

1、 电缆导体直流电阻及绝缘电阻 Cable conductor DC resistance and insulated resistance

|

标称截面 nominal sectional (mm2) |

导体结构 Conductor structure |

+20℃导体直流电阻(≤Ω/Km) Conductor DC resistance at 20℃ |

+20℃绝缘电阻(≥MΩ·Km) Insulated resistance at 20℃ |

||

| 种类Type |

根数/单线标称直径(mm) core No./ single nominaldiameter |

不镀锡 Untinned |

镀锡 Tinned |

||

| 0.5 | 5 | 16/0.20 | 39.0 | 40.1 | 15 |

| 0.75 | 1 | 1/0.97 | 24.5 | 24.8 | 12 |

| 0.75 | 2 | 7/0.37 | 24.5 | 24.8 | 12 |

| 0.75 | 5 | 24/0.20 | 26.0 | 26.7 | 12 |

| 1.0 | 1 | 1/1.13 | 18.1 | 18.2 | 11 |

| 1.0 | 2 | 7/0.43 | 18.1 | 18.2 | 10 |

| 1.0 | 5 | 32/0.20 | 19.5 | 20.0 | 10 |

| 1.5 | 1 | 1/1.38 | 12.1 | 12.2 | 11 |

| 1.5 | 2 | 7/0.52 | 12.1 | 12.2 | 10 |

| 1.5 | 5 | 30/0.52 | 13.3 | 13.7 | 10 |

| 2.5 | 1 | 1/1.78 | 7.41 | 7.56 | 10 |

| 2.5 | 2 | 7/0.68 | 7.41 | 7.56 | 9 |

| 2.5 | 5 | 50/0.25 | 7.98 | 8.21 | 9 |

| 4 | 1 | 1/2.25 | 4.61 | 4.70 | 8.5 |

| 4 | 2 | 7/0.85 | 4.61 | 4.70 | 7.7 |

| 6 | 1 | 1/2.76 | 3.08 | 3.11 | 7 |

| 6 | 2 | 7/1.04 | 3.08 | 3.11 | 6.5 |

| 10 | 2 | 7/1.35 | 1.83 | 1.84 | 6.5 |

2、电缆其它主要技术性能 Other major technical performances

型号Model:MKVV22、MKVV32、MKVV42、MKVV、MKVVR、MKVVP、MKVVP2、MKVVRP

|

序号 Serial number |

项目 Items |

技术性能 Technical performances |

|

| 1 | +20℃线芯直流电阻(≤Ω/Km) Core DC resistance at 20℃ | 见上表 See above table | |

| 2 | +20℃绝缘电阻(≥MΩ·Km) Insulation resistance at 20℃ | 见上表 See above table | |

| 3 |

5min耐工频交流电压试验 5min power frequency alternating current pressure test |

芯-芯Core-Core 芯-屏蔽Core-Shield 芯-铠装 Core-Armor |

3000V不击穿 3000V no breakdown |

| 4 | 单根垂直燃烧试验 Single wire burning test | MT386 | |

| 5 | 成束燃烧试验 Group burning test |

符合GB/T18380标准中B类成束燃烧试验要求 Conforms to GB/T18380 standard B kind group burning test |

|

上一页:矿用控制电缆执行标准

耐候阻燃矿用电缆推荐

电线电缆分类列表

联系我们

电话:0550-7778262

手机:(0)15385509815

邮箱:442312308@qq.com

地址: 安徽天长经济开发区

手机:(0)15385509815

邮箱:442312308@qq.com

地址: 安徽天长经济开发区

耐候阻燃矿用电缆相关文章

随机产品